This Tech Talk provides a basic overview of 3D printing processes and hazards. Part 2 in this series will provide additional details on exposure assessment methods and results.

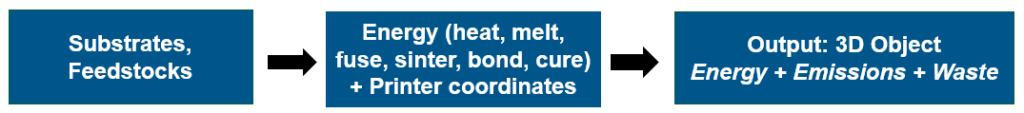

Additive manufacturing or “3D printing” is a set of technology platforms used to build 3D objects through the successive addition of material into the programmed shape. Metallic, ceramic, polymer, composite or other objects are made from 3D model data using printer parameters to deposit and join materials, usually layer by layer.

The use of 3D printing began three decades ago as a rapid-prototyping technology and has evolved and expanded to use in numerous industries, as well as by home hobbyists and in retail stores, schools, museums and public libraries. It’s a flexible platform that can produce customized objects with high complexity, where changes in design and production can be made through the computer model data and printer parameters. The technology is also highly accessible and relatively affordable, contributing to its rapid deployment from the workplace to homes, schools and other settings.

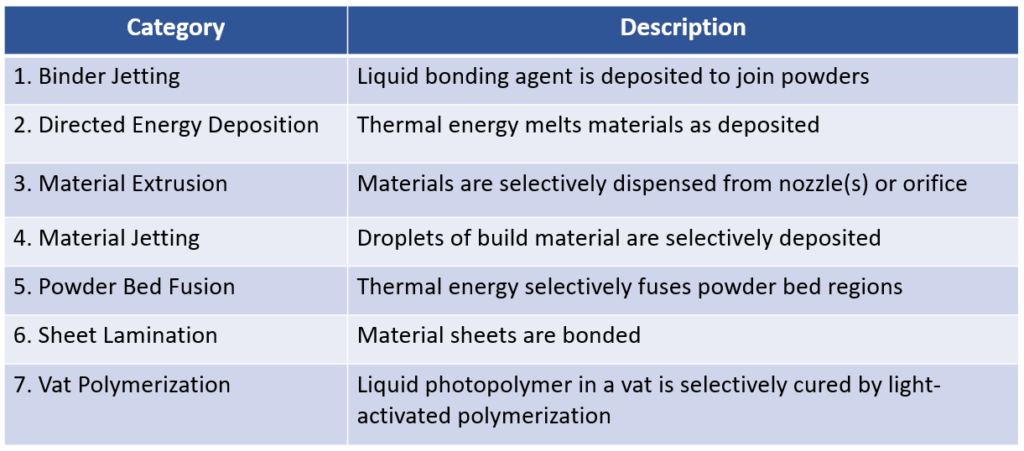

There are numerous technology platforms (some which require post-processing), materials, and equipment types. The International Organization for Standardization (ISO) describes additive manufacturing according to the following seven process categories [ISO/ASTM 59000]:

These broad categories describe how the 3D object is built; within a category there may be multiple different technologies and feedstock chemistries. Feedstocks may be in the form of a liquid; a solid filament, pellet, wire, film or sheet; granules or finely divided powder; or a colloid, depending on the process. For instance, powder feedstocks are used in binder jetting, directed energy deposition and powder bed fusion; materials are then joined by liquid bonding agents or thermal energy such as a laser, electron beam, or plasma arc. Material extrusion uses thermoplastic materials in solid forms; material jetting and vat polymerization use a liquid photopolymer resin.

Material extrusion, or fused filament fabrication (FFF), is a commonly used and relatively inexpensive 3D printing technology (e.g., desktop printers). Printers may have more than one head to print multiple types of materials at a time. Thermoplastic materials are used as feedstocks such as acrylonitrile butadiene styrene (ABS), polylactic acid (PLA), nylon, polycarbonate, and polyvinyl alcohol. Other common printing technologies include stereolithography (SLA), a type of vat polymerization, and material jetting using inkjet or polyjet techniques.

In some cases, advanced materials and other additives may be used in the printing process, such as engineered nanomaterials (e.g., metal nanoparticles in composite inks) or antimicrobial agents (e.g., silver ions). Certain applications involve printing at the micro- or nano-scale. A number of additive manufacturing technologies are being used for bioprinting applications to produce biological tissues, organs, and novel biomaterials and to manufacture customized implants, prostheses, drug delivery devices, and 3D scaffolds for tissue engineering. Bioprinting processes may involve metallic biomaterials, ceramic biomaterials, hydrogels and other biopolymers, and composites. [Chang et al., Materials, Jan 2018]

The potential hazards and exposure risks depend on the specific printing technique and application, materials, equipment and other factors. Hazards may include:

- Chemical:

- Metal powders, ceramics, polymers, resins, etc. as feedstocks

- Engineered nanomaterials, antimicrobials, etc. as additives

- Ultrafine particles (UFPs), Volatile organic compounds (VOCs), metal aerosols as air emissions

- Liquid and/or solid hazardous waste from printing or post-processing

- Physical:

- Fire or explosion (solvents, combustible dust, heat/electrical, compressed gas)

- Laser or UV radiation

- Noise

- Electrical, mechanical, hot surfaces

- Biological (for bioprinting): bioaerosols, surface microbial contamination

- Ergonomic: awkward postures, repetitive motions, high temperature

For additional details on potential hazards of additive manufacturing, see a recent review published by NIOSH scientists in the Journal of Occupational and Environmental Hygiene [Roth et al. , J Occup Environ Hyg, May 2019] or information from the NIOSH Science Blog April 2019 [https://blogs.cdc.gov/niosh-science-blog/2019/04/09/am/].

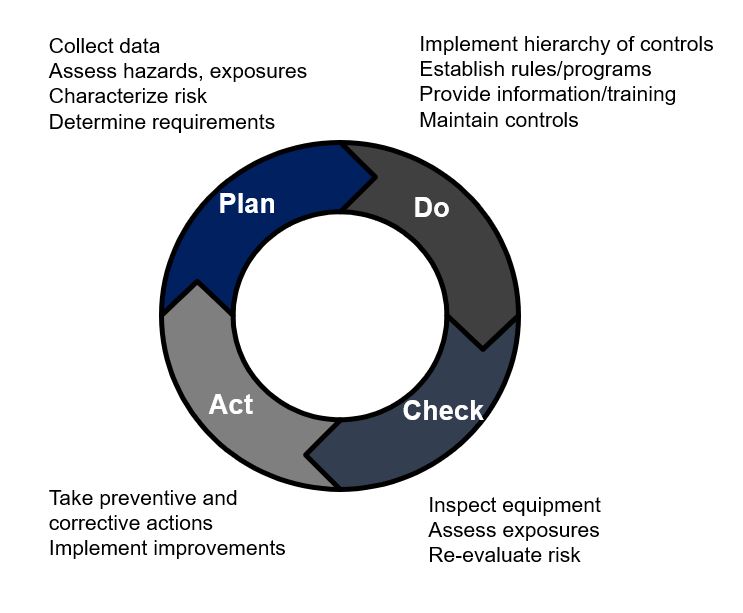

Environmental health and safety (EHS) professionals can use existing frameworks (see Figure 2) to evaluate the hazards, exposures and risks, and apply these results in selecting the technology, materials, work space and controls. Factors to consider in planning include:

- Printing technology, equipment, materials, and printing area (and post-processing if applicable)

- Scale (e.g., single benchtop unit, multiple units, large-scale manufacturing), frequency and duration of printing

- Feedstocks, support chemicals, and liquid or solid wastes produced

- Controls (e.g., equipment design, ventilation, work space, work rules, etc.)

- Communication and training

- Maintenance and monitoring needs

Part 2 of this Tech Talk series will outline exposure assessment methods and results from evaluating 3D printing emissions or exposures.