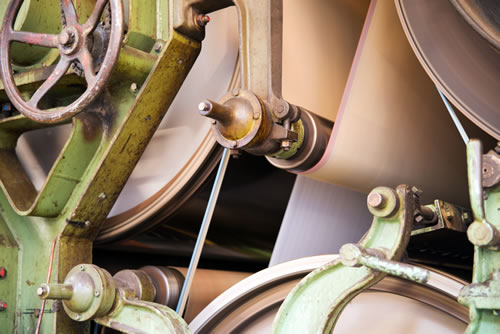

As one of OSHA’s top 10 most cited violations, a compliant and effective machine safeguarding program is paramount in ensuring worker safety and regulatory compliance. The basic principles of machine safeguarding state that employees must be protected from any of a machine’s points of operation that could potentially cause injury. This may be accomplished through fixed guards, interlock systems, or other safeguarding devices. Both older production equipment, as well as newly installed equipment, may be found to have inadequate safeguarding. The burden falls on end users to perform risk assessments to identify all hazards, and develop control measures when warranted.

Colden safety professionals evaluate safeguarding systems with respect to Occupational Safety and Health Administration’s machine safeguarding standards (29 CFR Subpart O), as well as other consensus standards. An effective machine safeguarding evaluation considers all modes of operation, evaluating the interaction of the employee and machine both during normal operations, and during servicing or maintenance activities. Machine safeguarding must be supplemented by an effective energy control (lockout/tagout) program that protects employees from hazardous energy sources during work activities when guards may be bypassed or removed.

Colden’s Services

- Machine safeguarding evaluations, from standard machine shop equipment to robotic systems

- Risk assessments

- Industry standard compliance (OSHA, ANSI)

- Evaluation of the interface between the client’s Machine Guarding and Lockout/Tagout practices and programs

- Safety education and training